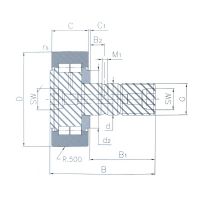

Cam followers with rolls and cage - NUKR Series

The rollers of this type of bearing have a very thick outer ring in order to guarantee the mechanical strength to reduce deformations due to loads and to bear high impacts.

The ring is cambered in order to prevent possible concentration of loads on the side bands of the bearing ring, to reduce the contact pressure, so less wear and longer life of the runway.

This type of product is a unique group and, being equipped with a pivot with threaded shank, it is very easy to install.

As far as lubrication is concerned, there are some holes on the side surface, and on both ends of the pivot.

As these rollers slide on flat bearing rings, it can occur an elastic deformation of their outer ring, so it is recommended to refer to loads as rollers (Cw and C0w).

Choose category

Intecom Srl specializes in manufacturing high-quality combined bearings, rolling bearings, and bearing profiles. Our combined bearings offer a compact and reliable solution for rotary motion. Rolling bearings ensure reduced friction and long service life. Our bearing profiles ensure stable and secure installation. Choose Intecom Srl for reliable and high-performance bearing solutions.

| Weight g | Dimensions(mm) | Pressure grease gun1) | Nut tightening pair | Load coefficients | fatigue limit load | Number of revolutions2) | |||||||||||||||||

| Intecom Code | with eccentric ring | D | d | C | rs | B | B1 | B2 | G | G1 | SW | M1 | C1 | d1 | Eccentric ring | din. | stat. | ||||||

|

h7

|

min

|

d1h9

|

B3

|

e

|

MANm

|

CWKN

|

C0WKN

|

PUWKN

|

nDGrease min-1

|

||||||||||||||

|

NUKR35

|

164

|

35

|

16

|

18

|

0,60

|

52

|

32,5

|

7,8

|

M16x1,5

|

17

|

8

|

3

|

0,8

|

20

|

-

|

-

|

-

|

NIP A2x7,5

|

58

|

15,0

|

16,8

|

2,22

|

6.500

|

|

NUKR40

|

242

|

40

|

18

|

20

|

1,00

|

58

|

36,5

|

8,0

|

M18x1,5

|

19

|

8

|

3

|

0,8

|

22

|

-

|

-

|

-

|

NIP A2x7,5

|

87

|

18,4

|

22,6

|

2,90

|

5.500

|

|

NUKR47

|

380

|

47

|

20

|

24

|

1,00

|

66

|

40,5

|

9,0

|

M20x1,5

|

21

|

10

|

4

|

0,8

|

27

|

24

|

18

|

1,0

|

NIP A2x7,5

|

120

|

28,0

|

35,0

|

4,40

|

4.200

|

|

NUKR52

|

450

|

52

|

20

|

24

|

1,00

|

66

|

40,5

|

9,0

|

M20x1,5

|

21

|

10

|

4

|

0,8

|

31

|

24

|

18

|

1,0

|

NIP A2x7,5

|

120

|

29,0

|

37,5

|

4,70

|

3.400

|

|

NUKR62

|

795

|

62

|

24

|

28

|

1,00

|

80

|

49,5

|

11,0

|

M24x1,5

|

25

|

14

|

4

|

1,3

|

38

|

28

|

22

|

1,0

|

NIP A3x9,5

|

220

|

40,0

|

50,0

|

6,30

|

2.600

|

|

NUKR72

|

1020

|

72

|

24

|

28

|

1,10

|

80

|

49,5

|

11,0

|

M24x1,5

|

25

|

14

|

4

|

1,3

|

44

|

28

|

22

|

1,0

|

NIP A3x9,5

|

220

|

44,5

|

60,0

|

7,60

|

2.100

|

|

NUKR80

|

1600

|

80

|

30

|

35

|

1,10

|

100

|

63

|

15,0

|

M30x1,5

|

32

|

14

|

4

|

1,0

|

47

|

35

|

29

|

1,5

|

NIP A3x9,5

|

450

|

69,0

|

98,0

|

12,10

|

1.800

|

|

NUKR90

|

1960

|

90

|

30

|

35

|

1,10

|

100

|

63

|

15,0

|

M30x1,5

|

32

|

14

|

4

|

1,0

|

47

|

35

|

29

|

1,5

|

NIP A3x9,5

|

450

|

79,0

|

117,0

|

14,40

|

1.800

|

Lip seal bearing (suffix PP); allowable operating temperature -30°C up to 100°C (continuous operation)

1) No. 2 grease fittings are included in the supply

2) No. of revolutions in case of continuous operation and grease lubrication